Industrial gear boxes refer to mechanical gear systems that change certain power traits for specific applications.

Generally speaking, a gear box decreases the speed and amplifies the torque of a power source so that we can use the power to move a load or exert pressure on a workpiece.

An industrial gear box has to work efficiently enough to achieve the desired performance while maintaining a reasonable power consumption level.

In order to meet such requirements, the making of the gear box parts becomes crucial.

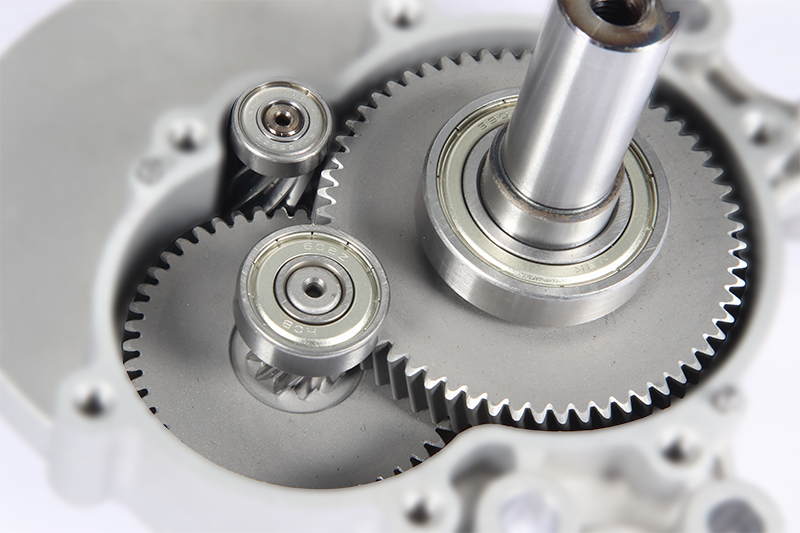

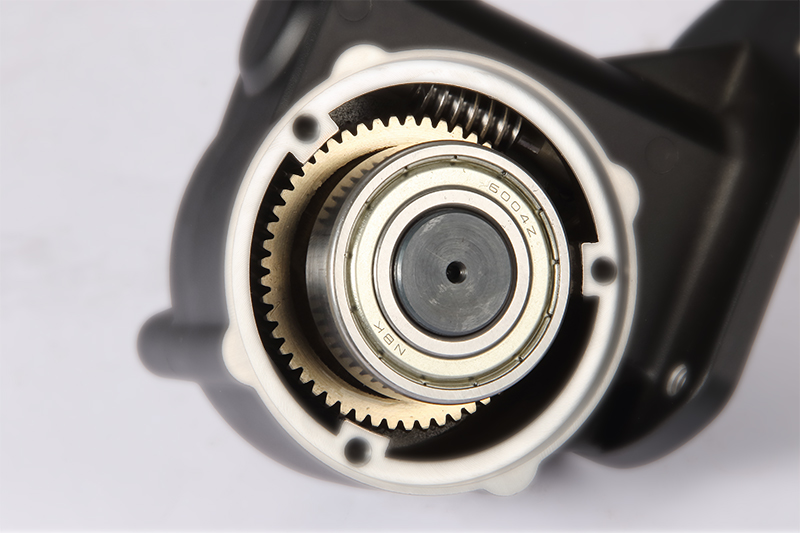

The gear box operation involves high pressure, heat, friction, impacts, etc.

The gears, shafts, and rolling elements must be able to withstand all that to ensure smooth and safe operation.

The materials used to manufacture each gear box part are not the same because every part requires different physical properties.

Some need to be rigid enough to withstand the impact.

Some need to absorb vibrations while meshing with others.

Some need to dissipate heat to avoid thermal fatigue.

CHUN YEH GEAR is an experienced industrial gear box part manufacturer.

We know the importance of using the right material to manufacture the right gear box parts.

The materials we use include stainless steel, aluminum, SNCM-220, SCM-415, SCM-440, S45C, plastic, PB2, PBC2, and ALBC2, ALBC3, just to name a few.

Feel free to contact us if you are interested in our gear box part manufacturing processes.